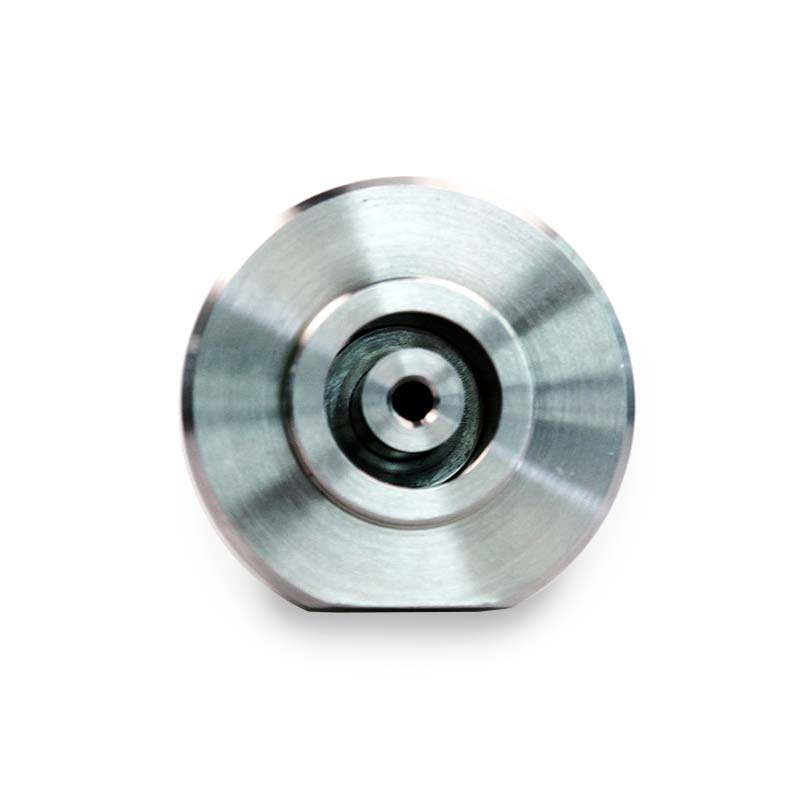

Fresatura, lavorazione tramite asportazione di truciolo, che consente di ottenere pezzi meccanici mediante utensile rotante e mantenendo fermo il pezzo attraverso morse o staffaggi. Si possono ottenere pezzi sagomati anche con profili molto complessi.

Meccanica Precisa, in ambito di fresatura utilizza centri di lavoro a 3 e 5 assi a controllo numerico, che differiscono dalle frese tradizionali per la possibilità di programmazione bordo macchina o con software CAD CAM.

Questo tipo di programmazione ( CAD CAM), preferita da Meccanica Precisa, permette di eseguire lavorazioni molto complesse usufruendo della tecnologia 5 assi sia in posizionato che in continuo.

La lavorazione 5 assi posizionato consente l’esecuzione di un pezzo attraverso un unico piazzamento nel quale si possono lavorare 5 facce contemporaneamente senza intervento dell’operatore con posizione di fresature, fori, filettature, maschiature ecc effettuate sempre rispetto allo zero pezzo.

Questo garantisce un’estrema precisione nella posizione delle lavorazioni sulle diverse facce.

La lavorazione 5 assi in continuo permette l’esecuzione di pezzi sagomati per i quali è necessario interpolare i 5 assi contemporaneamente. Questo genere di lavorazione consente la realizzazione di pezzi tipo eliche, pale e bloccaggi elicoidali ecc che, con macchine a 3 assi, non sarebbero realizzabili.